After adding decoders to a ready to run Faller Car System Car the next challenge is to completely build a car yourself. The truck or car to fit your landscape is probably not in the Faller catalog anyway.

To do this you will need a steering mechanism, a motor and gears. I have tested some gears and want to share my opinion with you.

Faller Setra

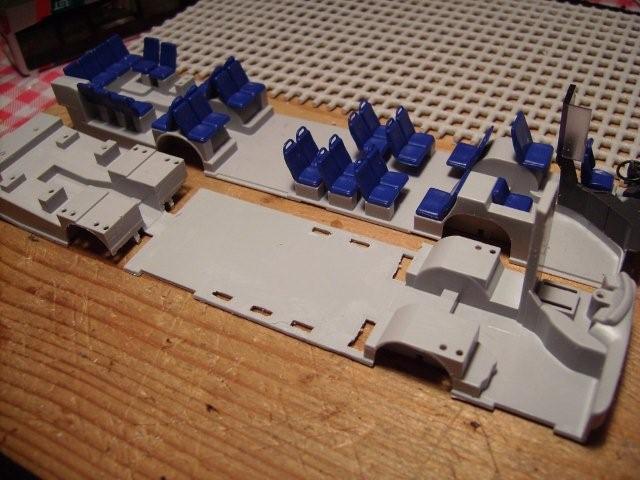

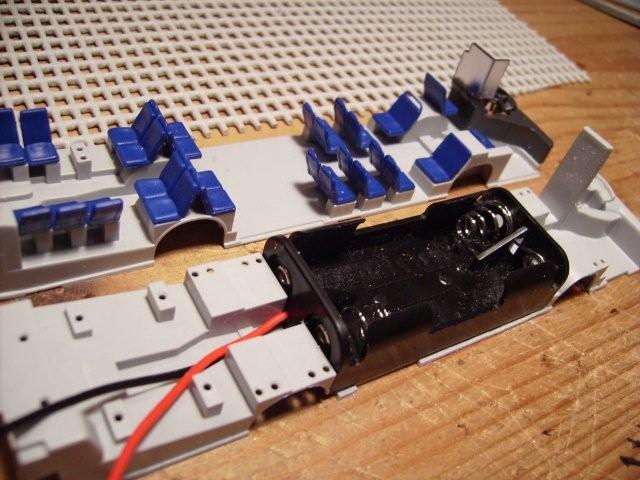

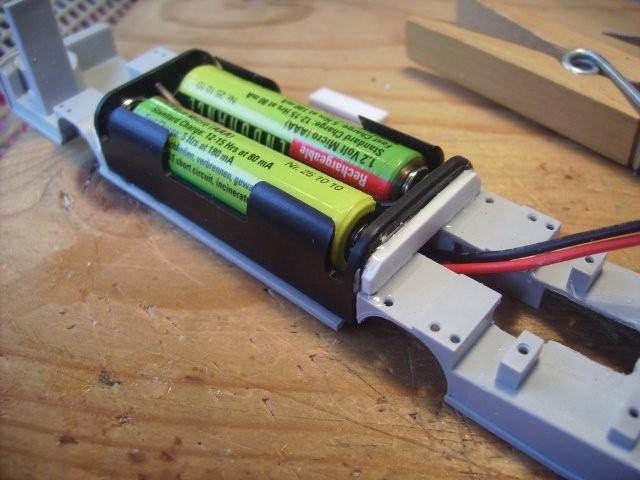

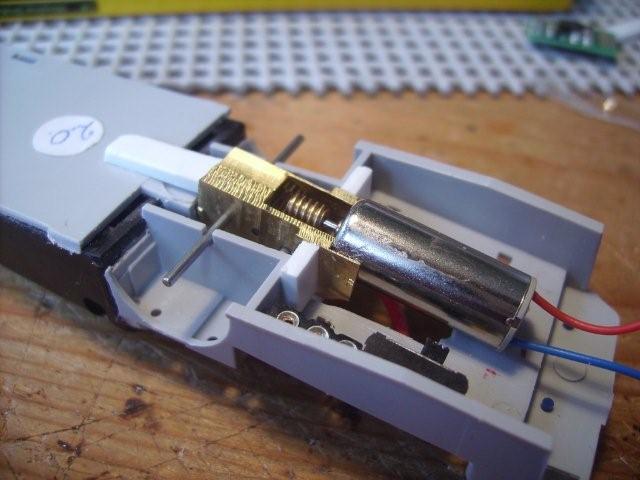

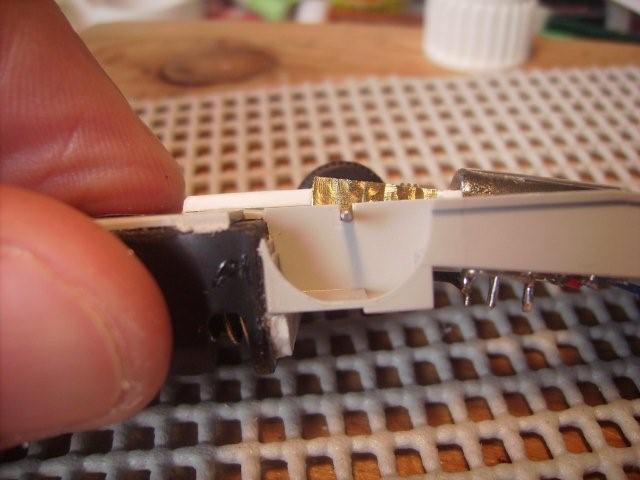

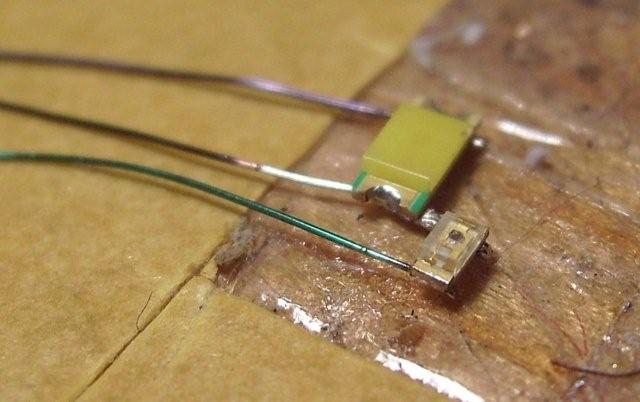

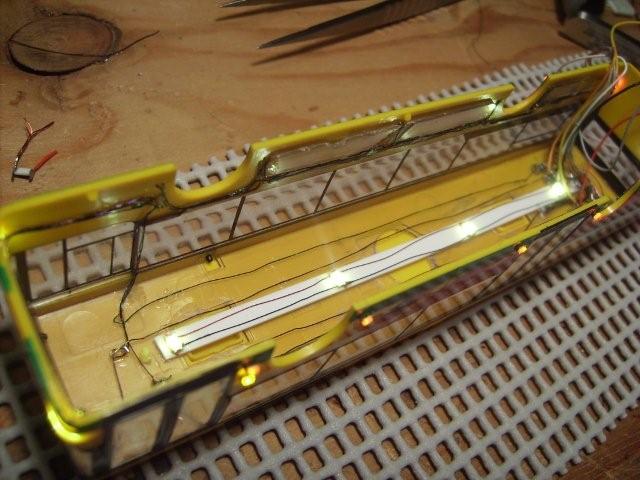

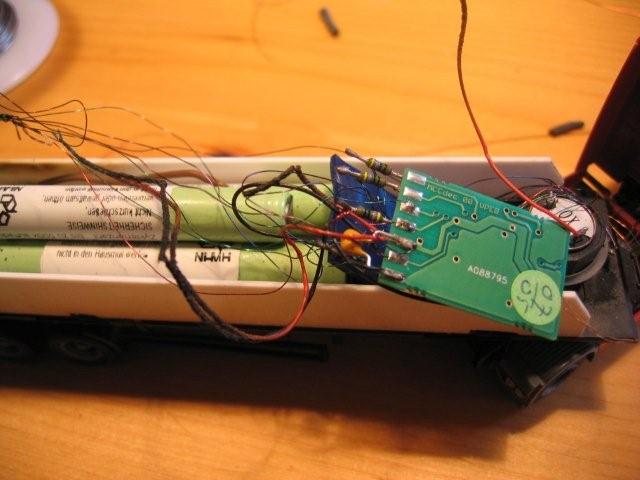

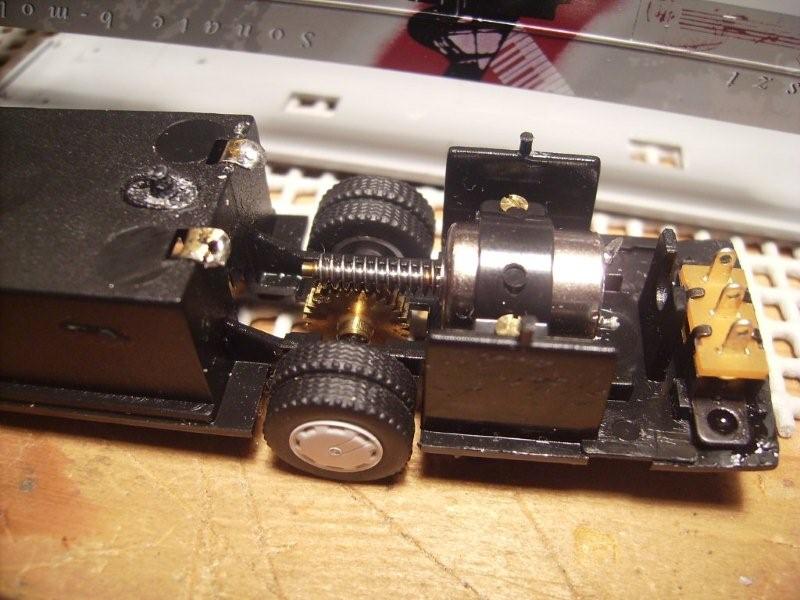

First in line is a standard Faller car. This is a motor and worm gear from the Faller Setra bus. This is the luxury set which includes head and tail lights and has beautiful white (according to the picture) interior lights. About the lights I will write later.

The worm gear in this bus is an improvement. Older buses I have seen have a very delicate construction which tend to break after a few hours. This construction is much better.

The motor sounds like we are used to, it behaves reasonable. The bus runs at a blazing speed!

In the picture you will not see any cables, they are all removed in preparation of the dinamo MCC decoder.

Lemo-Solar

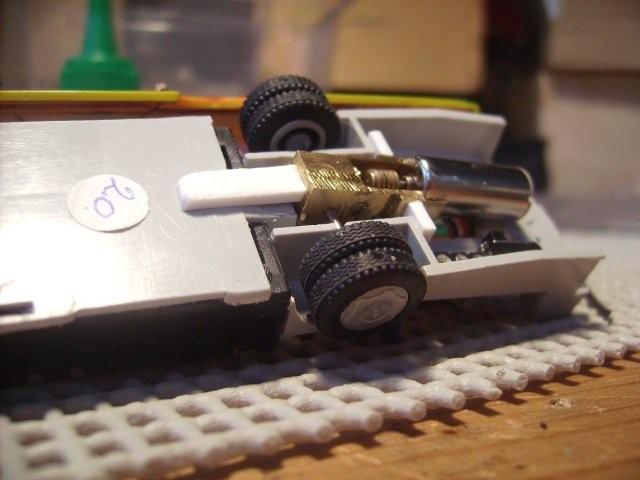

The first self-made trucks I made in 2007. In those days the only decent gears i could find were the Lemo-Solar gears.

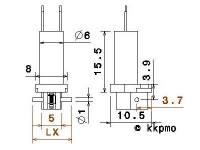

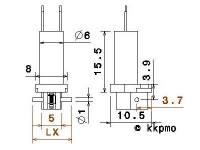

German details: Micro – Glockenankermotor mit Getriebe 15:1

Antrieb bestehend aus: Glockenankermotor 1016N003G, Winkelgetriebe 15:1 mit Schnecke und Schneckenrad ( Messing ), Doppelachse.

Als Antrieb faller Modelle M 1:87 oder Modellbauantrieb, Modelleisenbahnantrieb. Betriebsspannung 0,5 – 6 Volt, 18-280 mA, Masse: ( L x B x H ) 26 x 10 x 12 mm, Gewicht 10,7 Gramm, Abgangsdrehzahl 4,8 Volt = 1500 Upm, 3 Volt = 840 Upm, 1,5 Volt= 420 Upm.

This gear costs 46 euro excluding shipping (from Germany). This is a very expensive set. The motor is a real Faulhaber. It delivers a great deal of torc and takes a lot of electric current. We had to ad extra condensators to keep the power supply stable. It was distorting the reception. Technically speaking a good motor.

After using it intensively, as we do at Railz Miniworld, we find that the combination of a brass worm gear is not so good. The wear is disastrous. This is a very expensive set for the amount of kilometers it can run.

Microantriebe

This is a motor I found at the webshop from Mikroantriebe. The ordering went not without trouble. The first shipment never made it to my house. Only after numerous emails and threatening to make a PayPal dispute the second package was sent.

The motor of my choice was the “G20M660P Gearmotor with ratio20:1”. This one costs EUR 15,50. The cheapest motor I found ever. The English text on the website was very limited

If you switch to German you can find this:

“Getriebemotor mit 1 stufigem Schneckengetriebe. Gehause, Schnecke und Zahnrad aus hochwertigem POM gefertigt. Achse aus Stahl 24mm Dieser Motor kann z.B. mit unseren GWT Getrieben einfach zu 180:1 bis 400:1 Getrieben kombiniert werden oder z.B. direkt als z.B. Faller Car Antrieb eingesetzt werden”

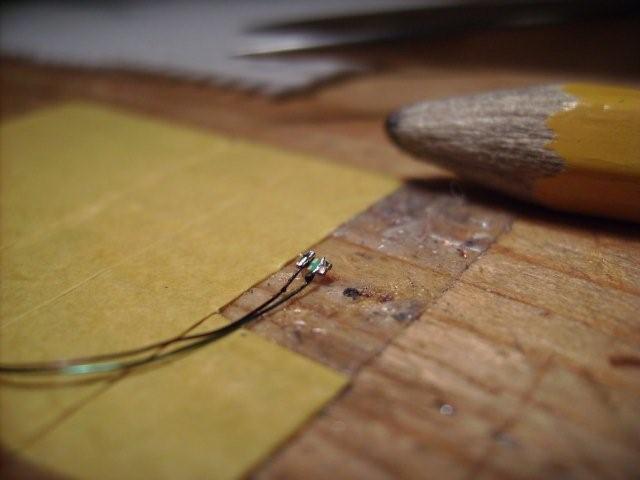

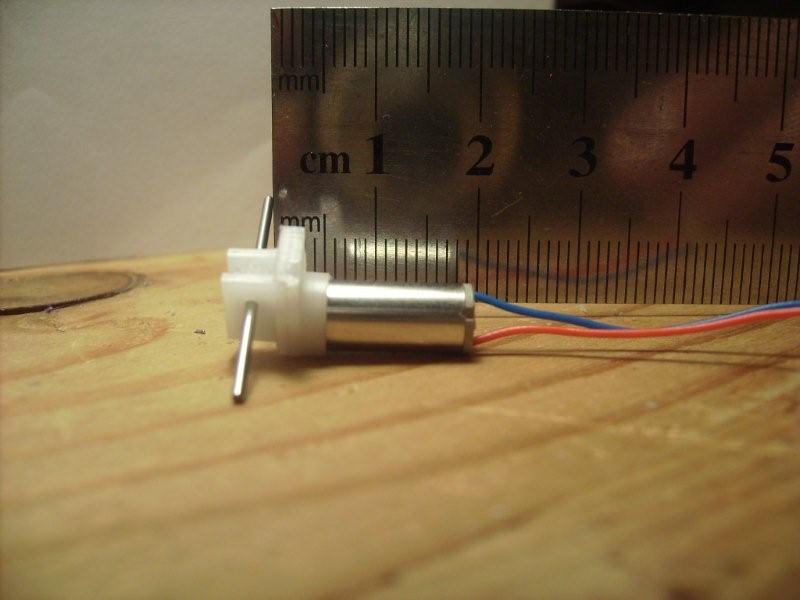

The “POM” was not translated in English so to me it was a suprise to see that the gears are plastic, not metal. Of course POM is a very good plastic, not uncommon in gears. This could work. The picture (right) on the current website was not there in december 2008.

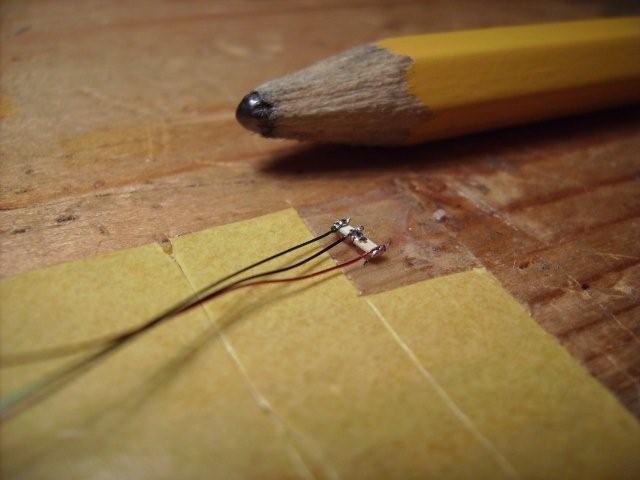

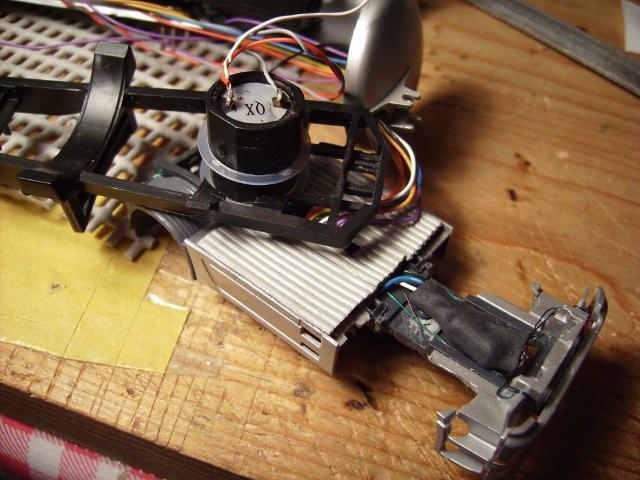

What catched my eye is the size of the little thing. Of course I had seen the dimensions on the website but never realized that it was this small.

Look a the next picture where you can see the Faller motor, a Faulhaber and the little G20M660P.

This is to small for a H0 truck or bus. Maybe a n-scale bus of a small H0 car.

The gear compared to a family car.

Or my next project.

Indeed, a fine match.

Gear box kit G90 with motor M705

First alternative for the little G20M660P is this gear. The G90 with M705 costs EUR 30,00 excluding shipping. Shipping from Germany to the Netherlands is 14 Euro!!!

To my suprise the gear is sold by Conrad too, EUR 29,99. If you pay with iDEAL shipping is free. It is the unfinished set, how hard can it be?

The set includes small holders to help with the construction, it also has very good instructions. No problem. The SolExpert advices to use the special Loctide 648. A normal super glue will work fine I thought.

looks beautiful! real engineering, what can go wrong?

And then reality hits in!

After one (1) minute of action the main gear came loose. I had to completely remove the gear from the bus. Glued the gear again and put it back in the bus. This took two hours! Result: one minute of driving before it failed again.

The special glue is not available in any normal shop in my home town. The 14 euro shipping prevented my from ordering the glue in Germany. At ebay I found a small fake bottle of loctide for 5 pounds and 2 pounds shipping. Within a week I was ready for a next attempt. Got everything out of the bus, glued the gear to the axle and waited. Glued the gear and motor back into the bus and….The gear was holding but to my disappointment it was glued not exactly perpendicular to the axle. After 2 cm it was completely stuck! There we go again. This is starting to get irritating!

With a new and somewhat thicker axle i got the gear perpendicular on the axle. Build everything together only to find the next problem. The gears runs but not smoothly.

In my last attempt I completely removed all the gears, including the small ones, check every detail and found some tiny glue residue. After removing this and removing the very very small milling imperfections the gears were finally working.

Final result: lots of motor noise and a bus that runs to slow. The 1:90 gear ratio is too much.

This cost me a lot of money and time without a good result; please, if you buy this gear, buy it assembled form the German site.

MikroModellBau

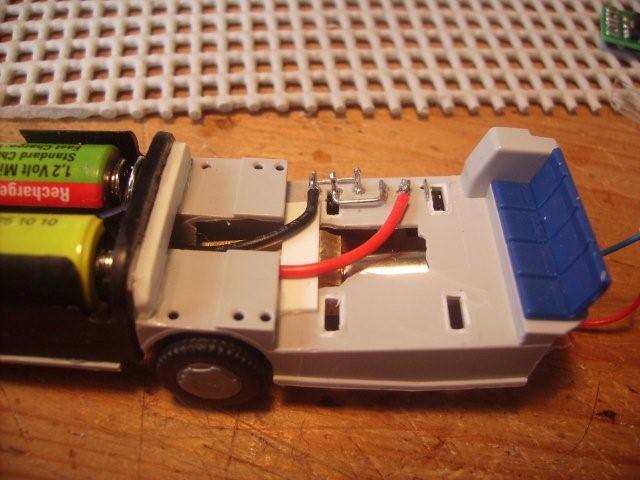

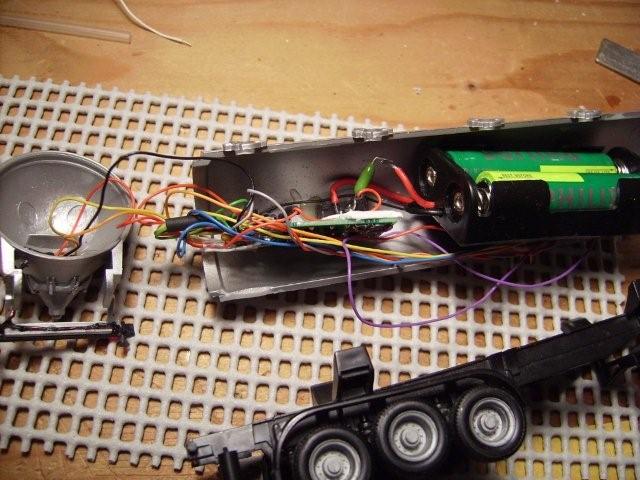

The next alternative is a set of gears form MikroModellBau.

I ordered two models. The KG-1048 and the KG-1019-30-s. They cost EUR 31,50 and EUR 25,00. Shipping 3,50. A order is confirmed by a email including a paypal transaction. Perfectly on time.

The gears are already put together and work very smoothly. There are very clear instructions included. Especially how to shorten the axles without damaging the internal gear. Because of my previous experience I know how important this is!

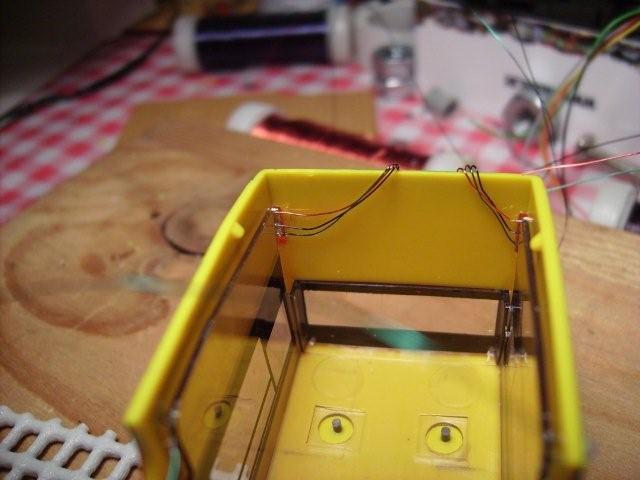

This second gear I tested in a bus. The flat top side is very good, the material glues very well.

The speed is fine. The bus has somewhat smaller wheels and still it is a little fast. This will be fixed by adjusting the decoder. As you can see I decided to wait before shortening the axles.

The first test run is a success. I’m finishing this one and make a 10 buses for Rails Miniword. We will see how long this gear will hold.

Conclusion

- Faller gear and motor are fine, wear is horrible. Fine for at home but not suitable for Railz

- Lemo-Solar. Very expensive, same wear.

- MikroAntriebe G20M660P.Cheap but not enough power for H0 trucks.

- SolExpert G90. Very hard to assemble yourself. Too slow!

- MikroModellBau KG-1019-30-s. runs smoothly. First experience very positive.

Do you have experiences with these motors and gears, please let me know. If you want I can add your comments to this article.